FOUNDER HISTORY

Founder History

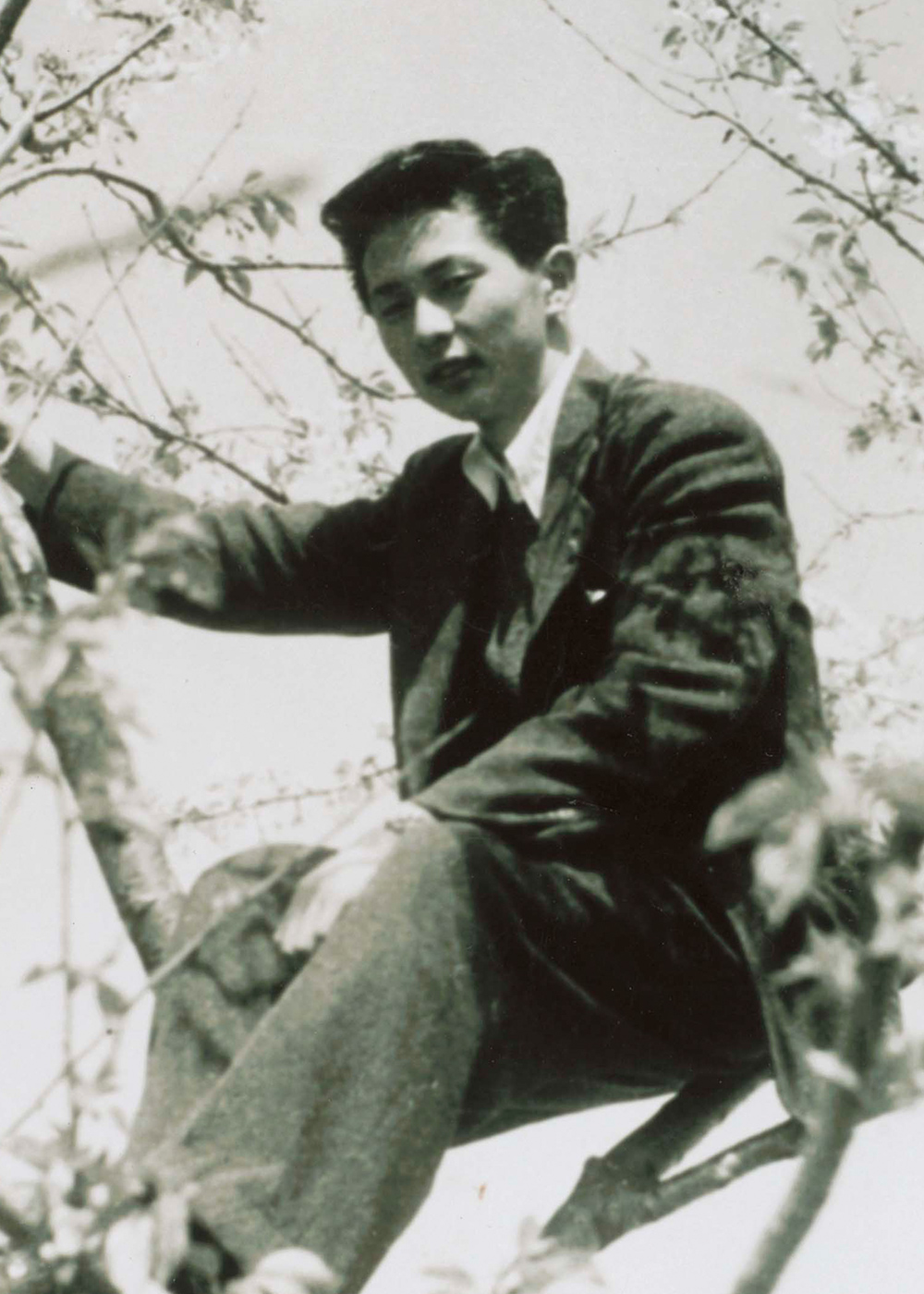

Why did you start trading business? ~Insatiable curiosity~

After joining Sakata Shokai (now Sakata Inx Corporation), I was first assigned to the General Affairs Department. As soon as I joined the company, I was put in charge of union measures and traveled around to various offices to study labor-related laws. After about two years, I was assigned as a secretary to an executive officer, but I didn’t like working at the head office, which was too rigid, so I asked to be assigned to the Trade Department, which had a more liberal atmosphere, and it was accepted.

Although I joined the trade department, the work of the trade department at that time was mainly selling imported goods domestically, and even here I could not suppress my curiosity. So I started exporting alone. In hindsight, I think I was very fortunate to be able to go abroad and work in an environment where I could work relatively freely. I also think that the company saw the merit of having me, a curious and unconventional person in every sense of the word, as the “cutting edge captain” to open up the export sales business. In the spring of 1957, I went on a 40-day business trip by myself to the ASEAN countries, and during my visit to the Philippines, then the most economically developed country in Asia, I discovered a new business possibility.

Why did you start an electronic components business as an ink manufacturer? ~”Inki” and “Denki” are one letter different (in Japanese)~

In the Philippines, I set my eyes on electronic components, which had nothing to do with ink. At that time, there were already more than 10 TV production plants in the Philippines. However, upon closer inspection, I found out that they were all assembly plants and most of the electronic parts were imported from the United States. Instead of selling televisions, I decided that the best market from the standpoint of needs would be to handle electronic components, which were highly versatile and could be incorporated into any electrical appliance, as they had the greatest potential in a world that would become increasingly electronic. The global market for inks was about 2 trillion yen at the time, and I thought, “If I do everything for 2 trillion yen, then the company’s development will be limited. Let’s do something else,” I thought.

When I returned to Japan, I immediately attended the Kansai Radio and Television Technical College (now the Kansai Television Electric College) to learn about electronic components. At the same time, I started working to secure a supplier. However, I was initially asked, “Why are you dealing with electronic components as an ink manufacturer? at first. In such a situation, I said, “Ink and Denki are one letter different in Japanese , but there is no difference in selling things! I proceeded with my activities.At that time, Matsushita Electric Industrial (now Panasonic Corporation) was the only company that comprehensively dealt with electronic components. I decided to start with the best company instead of the better, so I went to Matsushita Electric Trading Co., Ltd. alone without an appointment and negotiated desperately with my enthusiasm and tenacity . I was able to meet with Mr. Shozo Iimura, who was the managing director at the time.In the end, Mr. Iimura gave unusual visitor a chance, saying, “If you’re willing to help me organize the inventory of radio parts, I’ll leave it to you.With the inventory list in mind, I flew to the Philippines again and made appointments with radio manufacturers from one end to the other. In this way, even in the Philippines, with my natural enthusiasm and using broken English, I was able to receive orders for most of the parts on the inventory list and returned to Japan with a suppressed feeling of excitement.

This can be said to be the moment of birth of SIIX. Eventually, Sakata Shokai (now Sakata Inx Corporation) was granted the right to sell Matsushita Electric Industrial’s (now Panasonic Corporation) electronic components in the Philippines in 1959.

After that, why did you sell not only electronic components but also musical instruments, motorcycles, automobiles, CFC gas, etc.? ~Catching a follow-up wind~

Since then, I have sold a variety of products other than electronic components. It was around this time that I met Mr. Kakehashi, who would later establish Roland Corporation. Ltd. Mr.Kakehashi established Ace Denshi and Sakata shokai (now Sakata inx corporation) also invested in, we proceeded to manufacture and sell electronic musical instruments. At the same time, he noticed the Hammond organ made by an American electronic organ manufacturer and decided to sell it in Japan. At the time, there was already a company in Japan that had the rights to represent the Hammond organ, but I didn’t give up and went to the US headquarters to negotiate directly with President Sorensen.During the meeting, I told him, “The reason why your organs are not selling well in Japan is because they are too expensive. Even the cheapest type is more than the annual income of a Japanese. If you want to sell a large number of organs, the price has to be close to the monthly income of the country.If we can use our technology to produce low-end Hammond organs on an OEM basis, we will be able to sell them not only in Japan but around the world. After several rounds of negotiations, we succeeded in concluding an exclusive distributorship agreement for Hammond organs in 1968. Thereafter, Hammond International Japan was established as a joint venture between Hammond Corporation, Sakata Shokai, and Ace Electronics, and began selling low-cost Hammond organs in Japan and abroad.

On the other hand, I also started a business other than electronic components in the Philippines. The next thing I focused on was motorcycles. I wanted to make motorcycles available to the general public in the Philippines, as they were expected to expand as a means of transportation in the future. I visited Kawasaki Aircraft Industries (now Kawasaki Heavy Industries, Ltd.), which was not exporting at the time, with my business partner in the Philippines, Mr. J. ( Mr.Jesus V.del Rosario), who later became a lifelong friend, and after much effort, we obtained the commercial rights to export motorcycles to the Philippines in 1960.This business was further expanded in 1974, when the company established a joint venture with Kawasaki Heavy Industries, Ltd. to assemble and produce motorcycles. The hot climate of the Philippines also opened my eyes to the possibility of expanding the market for CFC gas used in air conditioners. Mr. J was also instrumental in this import.Subsequently, I continued to successfully expand sales of products unrelated to electronic components, such as forklifts and films. It is important to take advantage of the following winds of the market and place yourself in the most favorable environment.I also realized that what is necessary for success in business is not what you sell, but the universal importance of humanity and trust. The human relationships that I built in the Philippines, which were more than just family, blossomed into various forms of business like this.

How did you go from being an electronic components trading company to a PCB mounting business?

Why did you enter the PCB mounting business?

~The Benefits of Zero~

Our company history says that we started our EMS business in 1979. However, I cannot tell you exactly when we started our EMS business. This is because even before the term “EMS” was introduced to the world, we had been doing contract manufacturing using subcontractors in order to meet the needs of our customers.In that sense, there is no doubt that we are Japan’s pioneers in this business. As the production bases of Japanese companies began to spread to ASEAN countries, the needs of customers also changed. From procuring only electronic components, we began to offer kitting services to deliver electronic components in units to be fed into production lines. Contract manufacturing was an extension of this.”This is the result of our honest attempt to respond to the needs of our customers, such as, “It would be great if you could mount the components on the board and bring it to us. Therefore, we started contract manufacturing as a means of supplying materials.Our objective was to expand the distribution of electronic components, and EMS was a means to that end, not the true purpose of our company. At that time, we were amateurs in manufacturing and did not even have the resources for manufacturing within the company, so we invested in a reliable factory in Singapore and absorbed their manufacturing know-how.We thought that if we didn’t have the resources to handle it internally, we could just work with what we had. In fact, it is precisely because we don’t have the resources that we can enter into new businesses without the time and constraints of scrapping our existing resources. This is what I call the “The Benefits of Zero,” and I have been promoting this concept within the company. With the same belief, we continued to expand our contract manufacturing business in ASEAN and China.

Why did you take the lead over other companies in strengthening the EMS business for automobiles? ~Global Business Organizer~

I had been paying attention to the potential of the automobile market for quite some time, since I had been working in the Philippines assembling and selling motorcycles, as well as doing business as an agent for automobile exports in ASEAN countries. Later, as automobile production was shifting overseas in earnest, I thought that in-vehicle parts manufacturers would also shift to electrical components and outsource their production. Also, in terms of business continuity, the in-vehicle field is easy to plan, and once a business is started, there is a possibility that the next model will come along again.We thought that this would be an attractive field, not only for temporary purposes, but also to protect employment in various regions. In Japan, there was already a well-defined supply chain, but there was no such supply chain in other countries. We thought that if we could quickly enter this market, we could expect considerable expansion. I thought, “Why not? However, there is certainly an aspect of risk. Is it really possible to meet the demands of the automobile industry, which demands greater safety, without trouble? For these reasons, there were many voices of opposition within the company at the time. While there is certainly a point to this way of thinking, we thought that there was a lot to be gained by having barriers to entry, and we decided to enter this field as a challenge.Initially, we started with the in-vehicle AV field, which was relatively close to the consumer electronics field, and later we were able to deal with electrical components that are involved in human lives, such as driving, turning, and stopping. Today, the use of in-vehicle electrical equipment and outsourcing has expanded on a scale that defies imagination, and our bases are located in almost every major market in the world.

We have built this global network in response to the need for local production for local consumption and simultaneous global start-up. Currently, sales in the field of in-vehicle equipment account for more than half of our consolidated sales, and in addition to responding to the local production needs of Japanese companies, orders from European and American manufacturers of in-vehicle equipment are expanding. In the future, the meaning of the automobile itself will change from needs such as CASE. We believe that the market is still expected to expand, including integration with other segments. We will not compete on price or quantity, but on quality and service. This is the basic stance of our company.

What is the value that SIIX creates? ~Trust – SIIX We care.~

I took over as president after 10 years. I believe that my role now is to promote the sharing of SIIX’s values.

“There is a saying, “A fool learns from experience, a wise man learns from history. I don’t think that everything I have done has been the best, but I would like our employees to understand the importance of building trusting relationships with customers, as I mentioned in the first half, how to expand business, and the passion to overcome difficulties. We need to act with humility and learn with eagerness. As comrades in the same boat, we must have high ideals, but if our superiors and subordinates are not facing the same direction, the boat will not move forward. In order to do this, we must always remember to be fair. I myself would never consider promotion based on race or gender, and I would never do anything illegal. To use a golf analogy, we believe that the most important thing is to “go to the middle of the fairway” and eventually take a shortcut. We believe that the true reason for our existence is to build a relationship of trust not only with our customers but also with all our stakeholders. “I will continue to say, “If you have a relationship based on trust, you can breakthrough almost anything, because I was able to do it when I was an ink manufacturer